INSTALACIONES DE FABRICACIÓN

Nos enorgullecemos de nuestras modernas plantas de fabricación que emplean máquinas, sistemas y procesos de clase mundial

Estamos orgullosos de nuestras modernas plantas de fabricación que emplean maquinaria, sistemas y procesos de clase mundial. Los productos especificados se fabrican de manera eficiente y con los más altos estándares para nuestros leales clientes. Nuestras modernas instalaciones de producción regional ponen los inventarios al alcance de nuestros clientes en todos los Estados Unidos y alrededor del mundo.

FUNDICIÓN ARDMORE

Ardmore, Oklahoma

La fundición en Ardmore se construyó en 2001 y utiliza una línea de moldeado horizontal para la fabricación de piezas de fundición municipal. Con más de 190.000 pies cuadrados de espacio de fabricación, la instalación cuenta con tecnología de control ambiental de vanguardia.

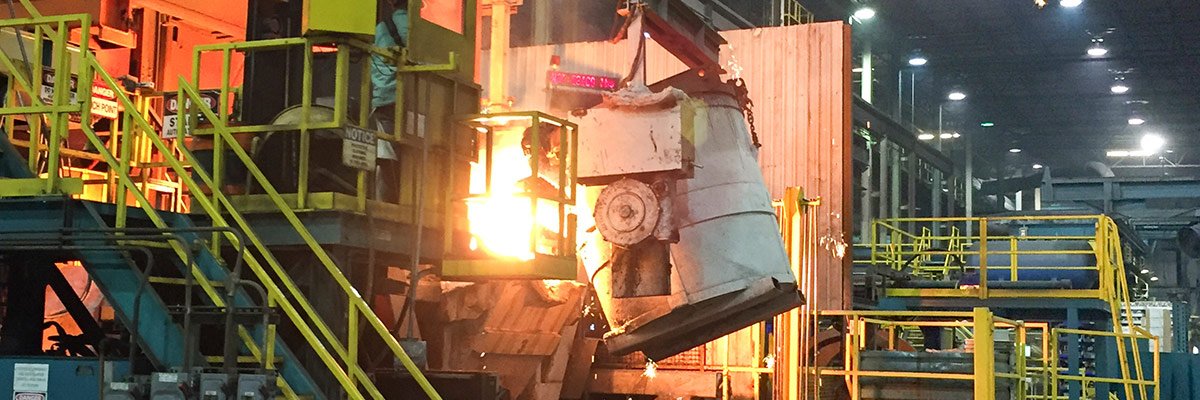

FUNDICIÓN EAST JORDAN

Warner Township, Michigan

Noviembre de 2018 marcó un hito importante para EJ, con el inicio de la producción en nuestra nueva y moderna planta de fundición Greenfield. Situada en un sitio de 200 acres, todo el edificio de fundición tiene 7,5 acres bajo techo, lo que equivale a aproximadamente 7 campos de fútbol. Cuenta con cuatro hornos eléctricos de fundición, dos líneas de moldeo y tecnología y automatización de vanguardia. La fundición en Warner Township reemplaza a nuestra fundición original en East Jordan, a solo 14 millas de distancia.

Muskegon Composites

Muskegon, Michigan

GMI Composites fue fundada en 1923. Adquirida por EJ en 2014, ahora se conoce como Muskegon Composites. Esta ubicación de 50.000 pies cuadrados fabrica soluciones de acceso compuesto para aplicaciones que requieren tecnología de compuesto de ingeniería.

FABRICACIONES YOUNGSTOWN

Youngstown, Ohio

Establecida en 2003, Fabricaciones Youngstown fabrica anillos de ajuste de metal, bandas de goma y rejillas de drenaje en nuestras instalaciones de 10.000 pies cuadrados.

FABRICACIONES SYRACUSE

Schroeppel, New York

Estamos orgullosos de comenzar la producción en nuestras instalaciones de Fabricaciones Syracuse en Schroeppel, Nueva York. En esta instalación, fabricamos escotillas de aluminio y acero, rejillas de acero, desagües de puentes, múltiples marcos y rejillas de drenaje DOT y otros productos fabricados a la medida. Las nuevas instalaciones nos permitirán servir mejor a nuestros clientes y, a una corta distancia de nuestra operación anterior, nos permitirán retener a nuestra fuerza laboral especializada, ¡quienes están emocionados de estar en una nueva instalación!

FABRICACIONES SALT LAKE CITY

Tooele, Utah

Adquirida en 2012, nuestras instalaciones de Salt Lake City tienen 20.000 pies cuadrados. Esta instalación se especializa en el diseño y fabricación de productos fabricados a la medida y escotillas de aluminio para las industrias de construcción y servicios públicos.

PRODUCTOS PARA AGUA EAST JORDAN

East Jordan, Michigan

La operación de Productos de Agua se encuentra en una instalación de 50.000 pies cuadrados en East Jordan, Michigan. Producen hidrantes y válvulas para sistemas de agua municipales. La instalación cuenta con máquinas-herramientas modernas, instalaciones de recubrimiento especial y un área automatizada de ensamblaje / prueba.