Carrying the Load for Americas Transportation Infrastructure

Choosing the correct load rating for infrastructure access solutions is a critical component to the long-term success of road projects.

LOAD RATING- IN THE MUNICIPAL INFRASTRUCTURE SPACE- IS DEFINED AS THE RANGE OF FORCE A COVER SURFACE OR FRAME CAN TAKE BEFORE FAILING. IT IS A USEFUL MEASURE TO INDICATE THE EFFECTIVENESS OF STREET INFRASTRUCTURE, AND ONE THAT HAS BEEN ADOPTED BY STATE DOTS, MUNICIPALITIES, AND PRIVATE DEVELOPERS ACROSS THE UNITED STATES.

Cette information est présentement disponible en anglais. Une traduction suivra sous peu.

Cette information est présentement disponible en anglais. Une traduction suivra sous peu.

Defined load ratings help users determine the best product for their project. Load rating standards in the US are governed by AASHTO (American Association of State Highway and Transportation Officials) and ASTM (American Society for Testing and Materials). These governing bodies not only specify criteria for load testing, but also for material quality. There are six rating classifications and their application depends on factors such as expected vehicular traffic and where in the environment the product will be used. The six rating classifications are Non-traffic, Light Duty, Medium Duty, Heavy Duty, Extra Heavy Duty and Airport Extra Heavy Duty.

PROCEDURE OVERVIEW

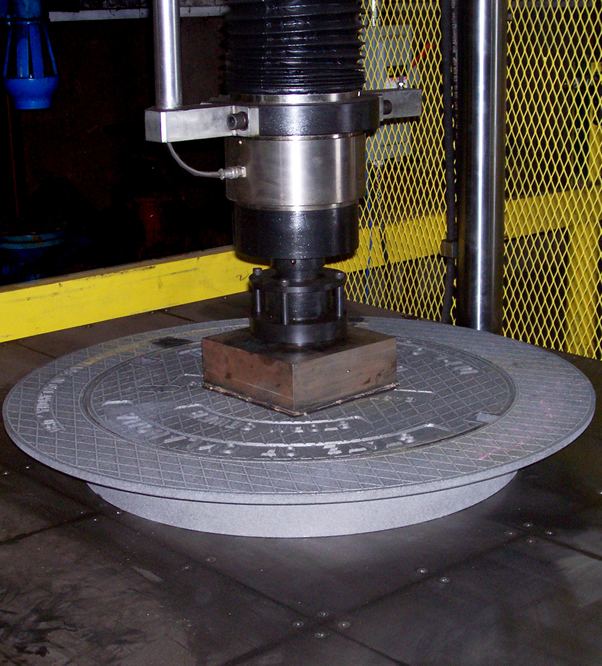

To understand these ratings, it’s important to look at how they are developed and what they stand for. Proof Load testing is the heart of the rating system. It is the standard test procedure to which AASHTO and ASTM hold all manufacturers accountable. The proof load testing procedure calls for the load to be concentrated on a 9" x 9" contact area in the center of the cover or grate and hold 40,000 pounds for one minute.

Following the test, the casting is carefully inspected. Cracks or permanent deformation are cause for rejection. EJ has a dedicated quality assurance group that focuses solely on material quality and ensuring our products meet industry standards. EJ takes this procedure very seriously, and our castings are typically tested far beyond the specified proof load. The casting's integrity is pushed to the maximum allowable load it can sustain and beyond, until structural failure occurs. This rigorous testing protocol is your assurance that EJ covers and grates will stand up to all expected traffic conditions. From this procedure, Acceptable Load Limits have been created that define the maximum weight allowed for each of the six ratings. Our quality group proof load tests products continuously to ensure EJ manufacturing quality remains consistent. Ensuring products meet and exceed load ratings has a lot to do with the material used in its creation.

Following the test, the casting is carefully inspected. Cracks or permanent deformation are cause for rejection. EJ has a dedicated quality assurance group that focuses solely on material quality and ensuring our products meet industry standards. EJ takes this procedure very seriously, and our castings are typically tested far beyond the specified proof load. The casting's integrity is pushed to the maximum allowable load it can sustain and beyond, until structural failure occurs. This rigorous testing protocol is your assurance that EJ covers and grates will stand up to all expected traffic conditions. From this procedure, Acceptable Load Limits have been created that define the maximum weight allowed for each of the six ratings. Our quality group proof load tests products continuously to ensure EJ manufacturing quality remains consistent. Ensuring products meet and exceed load ratings has a lot to do with the material used in its creation.

MATERIALS SELECTION

EJ manufactures construction castings using Gray or Ductile Iron. EJ uses quality raw materials and recycled scrap metals to achieve high grades of iron quality. Gray iron has an unequaled record of success as a material for construction castings. Gray iron, which incorporates both carbon and silicon, is one of the world’s best understood and most versatile construction materials used in engine blocks, cast iron cookware, and pump housings, among many other applications. It resists corrosion and abrasion, absorbs vibration, and has low sensitivity to notches (meaning that it is unlikely to shatter or fail due to minor damage). Infrastructure professionals who manage roadways and sewer networks appreciate its long, cost-effective service life. Ductile iron can be thought of as gray iron plus a ‘nodulizing element’, like magnesium, which reduces stress points in the metal matrix and inhibits cracks—this increased 'ductility' gives the material its name. Ductile iron has all the fine qualities of gray iron, and—without weighing more—is stronger, tougher, and more durable, with better impact resistance. It’s an ideal material for high performance castings in demanding installations such as ports and airports.

LOAD RATING DESCRIPTIONS

Having defined both the testing process and material quality for the load rating standard, what do the six ratings mean and where should they be used? EJ offers a set of guidelines that will help users define what load rating is best for their project. Our experienced sales team can also assist in this sometimes-technical area of choosing the best product for the application.

Non-Traffic - Generally, castings designated as non-traffic are intended for use in areas that are not subject to vehicle traffic. Generally nothing over 2,500 lbs. should be placed on top of these items. The max duty rating is under 2,500 lbs. Applications include: pedestrians, push lawn mowers, bicycles, and delivery handcarts.

Non-Traffic - Generally, castings designated as non-traffic are intended for use in areas that are not subject to vehicle traffic. Generally nothing over 2,500 lbs. should be placed on top of these items. The max duty rating is under 2,500 lbs. Applications include: pedestrians, push lawn mowers, bicycles, and delivery handcarts.

Light Duty - Light duty castings are able to withstand some vehicular loading, but are not designed to accept roadway traffic. The duty rating is a max of 2,500 lbs. These products may be subject to occasional traffic from process maintenance, mowers, etc. Use may include pedestrian walkways in parks and similar off areas consisting of predominantly foot traffic. Applications include: riding lawn mowers, garden tractors, or golf carts.

Medium Duty - Castings designated as medium duty accept loading from 16,000 - 40,000 lbs. These castings can accept standard traffic loading, and are in conformance with H-20/HS-20 (wheel load of 16,000 lbs. on a tire contact area of 10" x 20") or Federal Specification RR-F-621D (25,000 lbs. On a 9" x 9" load contact area). The duty rating is a max of 16,000 lbs. Applications include: compact to light passenger cars, parking lots, delivery vans, or infrequent slow moving trucks.

Heavy Duty - Casting must meet the requirements of AASHTO M306 to be classified as heavy duty. AASHTO M306 requires that castings bear a minimum of 40,000 lbs on a 9" x 9" area. The max duty rating is 40,000 lbs. This class is the workhorse of the ratings system and is the most common rating for products found in streets and highways. Applications include: passenger cars and trucks at posted traffic speeds, semi-trucks, or pneumatic tire industrial equipment.

Heavy Duty - Casting must meet the requirements of AASHTO M306 to be classified as heavy duty. AASHTO M306 requires that castings bear a minimum of 40,000 lbs on a 9" x 9" area. The max duty rating is 40,000 lbs. This class is the workhorse of the ratings system and is the most common rating for products found in streets and highways. Applications include: passenger cars and trucks at posted traffic speeds, semi-trucks, or pneumatic tire industrial equipment.

Extra Heavy Duty - Casting has been proof load tested to 100,000 - 200,000 lbs. This meets the design loading associated with the FAA wheel loading. The max duty rating is 100,000 lbs. This rating is for applications in extreme environments where excessive loads are to be expected. Applications include: general aviation aircraft such as Lear jets and private planes, port facilities, hard tire industrial equipment.

Airport Extra Heavy Duty - Casting has been proof load tested to a minimum of 200,000 lbs. This includes an additional safety factor over FAA design loading. The max duty rating is 200,000 lbs. This rating specifically applies to Airport and Port environments where frequent loads exceed 100,000 lbs. Applications include: wide body passenger/cargo aircraft, mining equipment, port facilities with high wheel loads that involve braking and turning (i.e. equipment used to move, lift and transfer cargo containers)

Choosing the correct load rating for infrastructure access solutions is a critical component to the long-term success of road projects. Knowing load rating weight limits and the applications they support can help guide users to the correct product solution. EJ offers products in every load rating classification and our dedicated team can help tailor a solution to fit your application.

REQUEST A LUNCH & LEARN

An EJ expert will set up a time and location convenient to you. We'll share with you industry trends, case studies and solutions for common applications in the infrastructure industry. Contact us today!

How much will it cost?

It's FREE! We want to share our years of expertise with your team. We hope that you'll find our solutions and expertise will help you grow your business.

What equipment is required?

Our Lunch & Learn presentations typically require an area suitable for a PowerPoint presentation. We'll bring the computer, a projector and FOOD!