DUROSTREET® Composite Access Assembly

Heavy Duty Roadway Applications

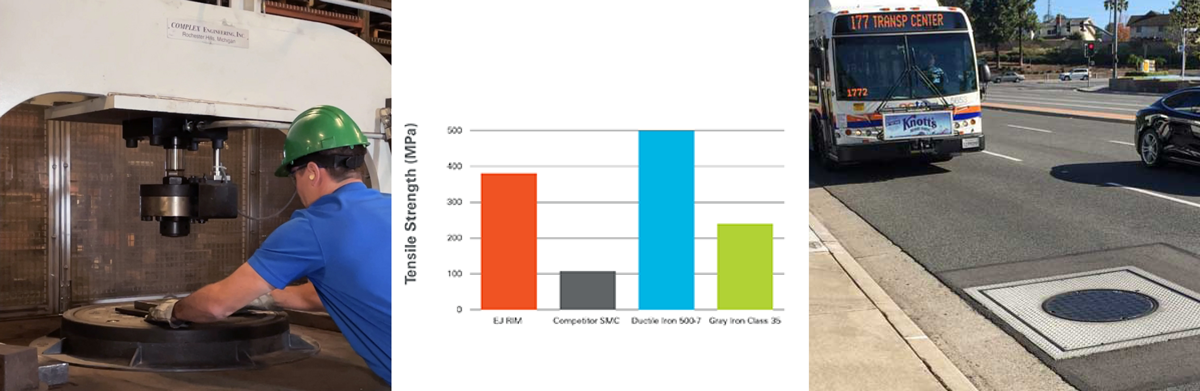

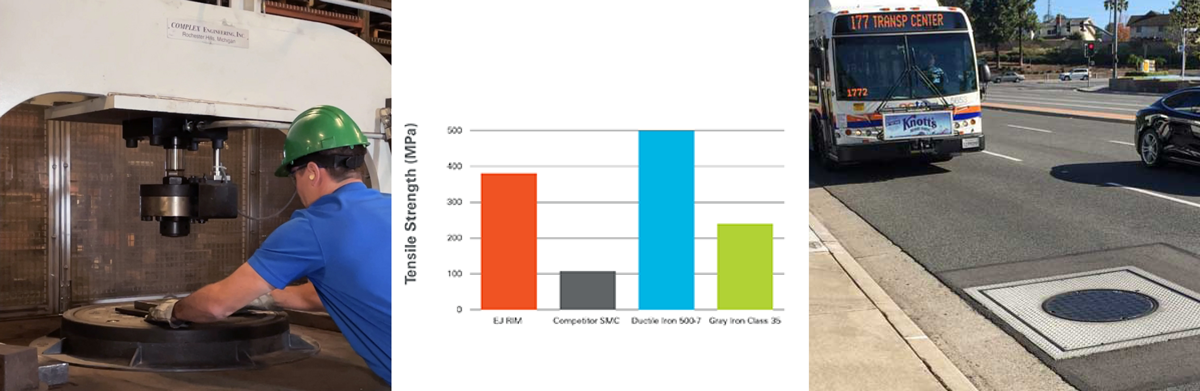

No Shortcuts on Strength

Cette information est présentement disponible en anglais. Une traduction suivra sous peu. The DUROSTREET® access assembly is the strongest and most durable composite manhole cover on the market. Since safety is our top priority, we proof load test to 50,000 lb (per AASHTO M306 (H25) standards for cast iron) and exceed industry standards by fatigue testing to 2 million cycles at 16,000 lb. Our superior composite technology also makes it the lightest weight heavy duty cover on the market, making it safer for workers.

Take a look inside the manufacturing facility in Muskegon, Michigan to see how our DUROSTREET access assembly is made:

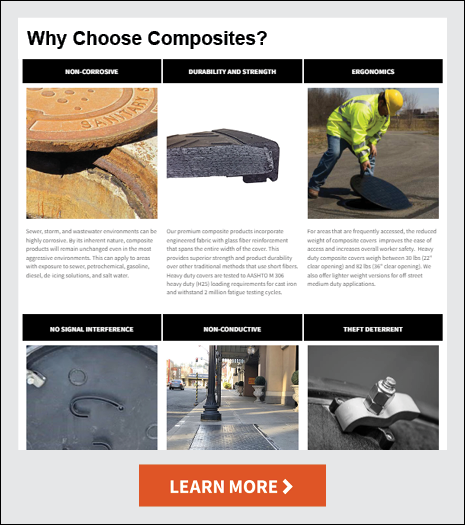

Why Composites?

Composite manhole frames and covers are anti-corrosive, have non-conductive properties, and eliminate signal interference. Their reduced weight improves the ease of access and overall worker safety, and with no value for scrap metal, theft can be significantly reduced. Learn more about the Benefits of Composites

Not all Composite Covers are Built to Last

Some new to the market composite products are made of poor quality materials that may look the part, but perform poorly in long term durability performance and can impact composite perception overall. This can create a dangerous safety hazard if composite covers are failing in the field. Using compression molding technology costs less, however, these products have inferior durability and long term performance—and independent research as shown in our Composite White Paper confirms this.

The DUROSTREET access assembly delivers superior strength and durability compared to other composite options on the market.

Advantages

Extreme Strength, Durability, and Wear Abrasion

DUROSTREET covers tested over three times as strong as compression molded composite products in independent lab testing. They are fatigue tested to 2 million loading cycles at 16,000 pounds of load and are designed to withstand heavy roadway traffic. The data clearly shows that continuous glass fibers have significantly stronger properties than short glass fibers. Taking into account the importance of the strength-to-weight ratio, it’s clear that by using continuous glass fibers, significantly stronger and lighter covers can be produced. They also provide superior wear and abrasion per ASTM D4060-14 and proved to be six times more effective than other composite products manufactured using compression molding.

Light Weight for Ergonomics

Our covers are the lightest heavy duty composite covers on the market for roadway use, while taking no shortcuts on strength. They weigh between 30 lbs (22" clear opening) and 82 lbs (36" clear opening). The optimized strength-to-weight design and one-person operation improves ease of access and overall worker safety.

Manufactured to a Higher Standard

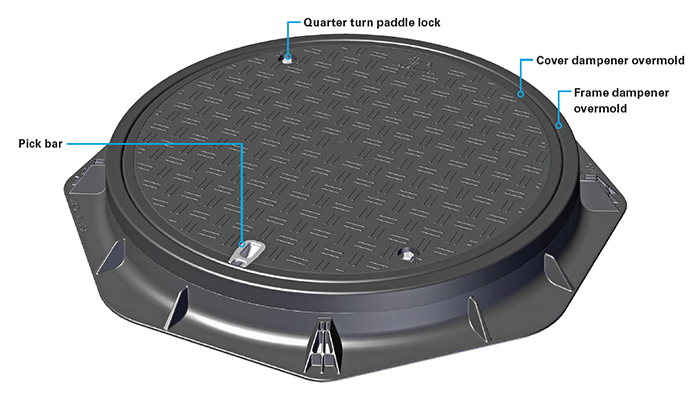

DUROSTREET covers are produced with Reaction Injection Molding (RIM). Long continuous strands of glass fiber reinforcement incorporated in the cover stretch from one side to the other and polyurethane resin components are mixed and injected into the mold under heat and high pressure. They are also the only composite product on the market with durable overmold around the perimeter of the cover and frame that dampens traffic vibration and improves wear resistance.

As the leading composite manufacturer, we have built up over 25 years of tradecraft and know-how when it comes to producing composite products. In addition to our expertise in the US, we collaborate with our colleagues in Europe on product design to ensure best-in-class manufacturing and longevity in the field.

Retrofitting with Cast Iron Frames

We offer custom sized covers that are designed to use with existing cast iron frames. We have more custom sizes than any other composite manufacturer, as we don't use a one size fits many approach. Our vast history of engineering and producing iron frames and covers makes us the experts in fitting a cover into an iron frame. Contact your EJ Sales Representative for assistance with custom applications at 800 626 4653.

Extreme Strength, Durability, and Wear Abrasion

DUROSTREET covers tested over three times as strong as compression molded composite products in independent lab testing. They are fatigue tested to 2 million loading cycles at 16,000 pounds of load and are designed to withstand heavy roadway traffic. The data clearly shows that continuous glass fibers have significantly stronger properties than short glass fibers. Taking into account the importance of the strength-to-weight ratio, it’s clear that by using continuous glass fibers, significantly stronger and lighter covers can be produced. They also provide superior wear and abrasion per ASTM D4060-14 and proved to be six times more effective than other composite products manufactured using compression molding.

Light Weight for Ergonomics

Our covers are the lightest heavy duty composite covers on the market for roadway use, while taking no shortcuts on strength. They weigh between 30 lbs (22" clear opening) and 82 lbs (36" clear opening). The optimized strength-to-weight design and one-person operation improves ease of access and overall worker safety.

Manufactured to a Higher Standard

DUROSTREET covers are produced with Reaction Injection Molding (RIM). Long continuous strands of glass fiber reinforcement incorporated in the cover stretch from one side to the other and polyurethane resin components are mixed and injected into the mold under heat and high pressure. They are also the only composite product on the market with durable overmold around the perimeter of the cover and frame that dampens traffic vibration and improves wear resistance.

As the leading composite manufacturer, we have built up over 25 years of tradecraft and know-how when it comes to producing composite products. In addition to our expertise in the US, we collaborate with our colleagues in Europe on product design to ensure best-in-class manufacturing and longevity in the field.

Retrofitting with Cast Iron Frames

We offer custom sized covers that are designed to use with existing cast iron frames. We have more custom sizes than any other composite manufacturer, as we don't use a one size fits many approach. Our vast history of engineering and producing iron frames and covers makes us the experts in fitting a cover into an iron frame. Contact your EJ Sales Representative for assistance with custom applications at 800 626 4653.

Standard Features

• Tested to the proof load requirements of AASHTO M306 Heavy duty (H25) for cast iron

• UV resistant—tested to ASTM G154-16 testing standard Cycle 1 for 1600 hours. Resist the impact of UV twice as well compared to SMC

• Cover dampener and frame dampener (overmold)

• Color: Black

• Pick bar made of 316 stainless steel

• Quarter turn paddle lock with penta head made of 316 stainless steel

• Five year limited warranty

• Made in the USA

Options

• Special lettering

• Custom logos

• Additional security locking

• Custom shapes: square or rectangular

• Custom diameters to fit existing iron frames

• Flame retardant resin

• AMR attachments

• Heat transfer protection

• Watertight Level 1 (L1) with optional o-ring

Learn More

Talk to an expert at EJ to find out how the innovative solutions by EJ can work for your next project. Contact us today or schedule a Lunch and Learn.

Additional Composite Products

Off-Street Applications |

|---|

|

DUROWALK® Access Assembly

|

Composite Handholes |

|---|

|

DUROCOM™ Composite Handhole

|