Product Briefs

5000 Hinged Drainage Grate

Improve ease of access with the 5000 cast iron hinged drainage grate

Link Text

Link Text

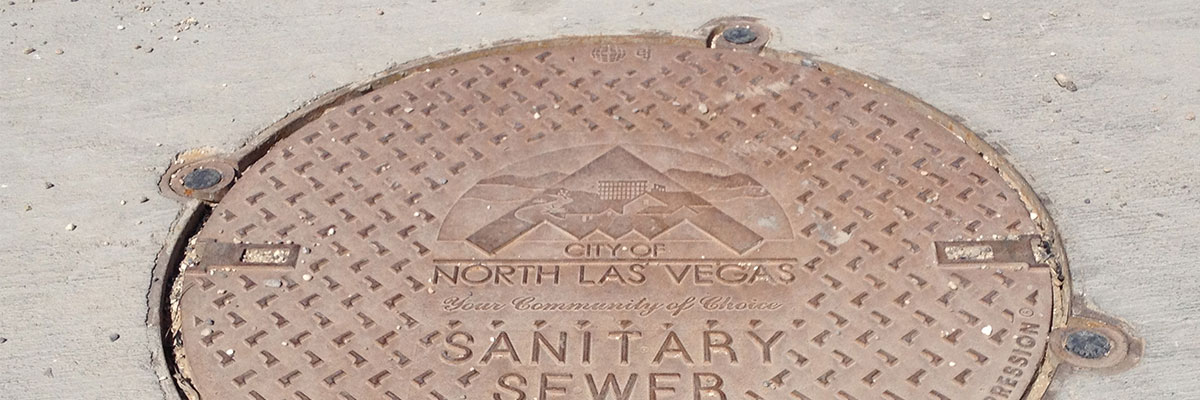

DUOSEAL® Watertight Access Assembly

Watertight manhole cover and frame prevents inflow and overflow

Link Text

Link Text

ERGO® XL ACCESS ASSEMBLY

A larger version of the ergonomically designed ERGO® Access Assembly

Link Text

Link Text

Explosion Mitigation Manhole Solution

Keep your underground power networks covered and secure.

Link Text

Link Text

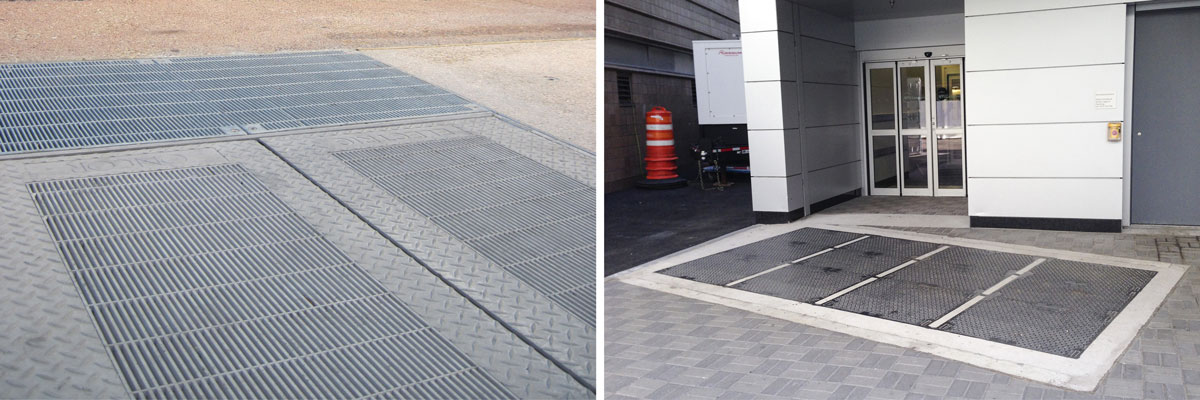

Hinged Trench Assembly

Ergonomic drainage solution for supply lines and collection systems

Link Text

Link Text

INFRA-RISER® Adjustment Riser

Engineered to adjust manhole covers and catch basins to grade

Link Text

Link Text

Retrofit Top Mount Aluminum Access Hatches

Does your municipality or water system have a dangerous hatch that needs to be replaced?

Link Text

Link Text

REVOLUTION® Access Assembly

Designed specifically for elevated structures and raised access points

Link Text

Link Text

SELFLEVEL® Asphalt Access Assembly

Engineered to keep manhole covers flush with the pavement

Link Text

Link Text

SELFLEVEL® Concrete Access Assembly

Engineered to keep manhole covers flush with the pavement

Link Text

Link Text

SELFLEVEL® VALVE BOX TOP

Drivers will appreciate the smooth ride and you'll appreciate prolonged road life

Link Text

Link Text

WaterMaster® Fire Hydrants

Dry-barrel fire hydrants - available in 250 or 350 psi and backed with a 10 year limited warranty

Link Text

Link Text

.jpg)