Access Hatch Solves a Noisy Problem

Ductile Iron Access Hatch Installation – Sandy, Utah

The City of Sandy, Utah is situated near the Wasatch Mountains about 15 miles south of Salt Lake City. As the fifth largest city in the state, Sandy is home to the Rio Tinto Stadium, Mountain America Expo Center, and numerous performing arts venues and museums. The city offers residents and tourists just about anything they could want or need: outdoor recreation, shopping centers, entertainment, and everything in between. With the hustle and bustle that is synonymous with city life, one access hatch along South Highland Drive had become quite the headache for everyone – literally.

A Noisy Problem

The Metropolitan Water District of Salt Lake & Sandy (MWDSLS) had received numerous complaints from the community about an access hatch, provided by another company, located in the roadway. When driven over, the unit made a horrible racket. It was positioned within the drive line of traffic, which made it difficult to avoid. Reports of the noise were so prevalent the MWDSLS had no choice but to find a solution, and fast.

After a decade of stress from traffic, the bolts used to keep the hatch cover closed and in place had become sheared. This left the cover free to shift when driven over, causing a significant amount of noise. Upon inspection by EJ Branch Manager Craig Anderson, he noted the cover may have been loose within the frame to begin with, which allowed it to wiggle and put pressure on the bolts. This ultimately caused the bolts to break. To make matters more challenging, the bolts were drilled and tapped into the frame, meaning they could not simply be replaced. Because of this bolting failure, the MWDSLS was adamant about a floating bolt option.

An Access Hatch with Innovative Upgrades

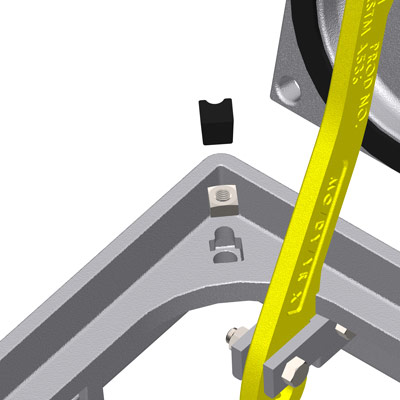

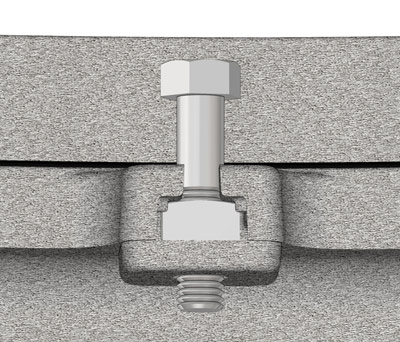

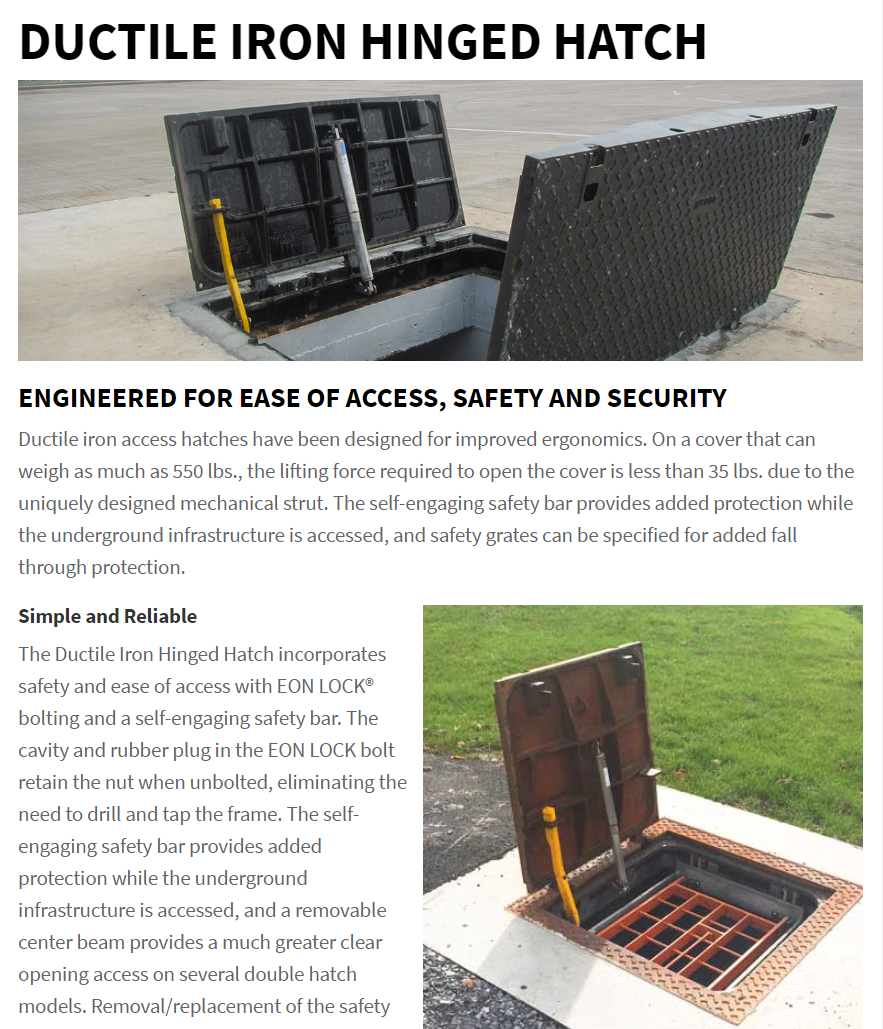

With careful consideration, Anderson proposed an EJ ductile iron hatch that included a replaceable bolting feature. Though the MWDSLS was leery, Anderson explained that with the EON LOCK® Bolting system, the bolts would fasten into replaceable nuts, not directly into the frame. This is achieved by creating a horizontal access point in the cast frame allowing nuts to be inserted or replaced if threads become stripped. Anderson also reassured them that shearing of bolts had not been an issue with EJ ductile hatches in the past; however, if this or any other issue were to occur with the bolting, it could easily be replaced.

“Because the bolt and nut are designed to move (float) a little, it keeps the shear stress off of the bolt, and of course it is extremely easy to replace if it is damaged,” said Anderson.

The new hatch would also include a strong and durable EPDM gasket for sound dampening; something the existing hatch did not have.

Despite their initial hesitation, the MWDSLS decided to give it a try. Since the first installation on South Highland Drive, they have placed additional orders for ductile iron hatches from EJ to replace existing ones. Six years later, the city is “very pleased with the function and operation of the EJ units,” said Anderson. “We just bid another project for MWDSLS in Draper, UT for three more of these identical units to be installed in direct traffic roadway.”